FTTH Drop Cable: Unraveling the Key to High - Speed Home Connectivity

October 17, 2025

Introduction

In the digital age we live in, high - speed and reliable communication networks have become the lifeblood of modern society. Among the key components enabling this seamless communication is the FTTH Drop Cable (Fiber - To - The - Home Drop Cable). As the demand for faster internet speeds, high - definition video streaming, and real - time online interactions continues to soar, FTTH Drop cables play a crucial role in bridging the gap between service providers and end - users.

These cables are the final link in the fiber - optic network infrastructure, directly connecting homes and small businesses to the broader fiber - optic backbone. They are responsible for delivering ultra - fast broadband services, revolutionizing the way we work, study, entertain ourselves, and communicate with others. Without FTTH Drop cables, the promise of gigabit - speed internet and the full potential of emerging technologies such as smart home devices, virtual reality, and cloud - based services would remain unfulfilled. So, let's delve deeper into the world of FTTH Drop cables, exploring their structure, types, installation, and much more.

1. What is FTTH Drop Cable

1.1 Definition and Concept

FTTH Drop Cable, short for Fiber - To - The - Home Drop Cable, is a crucial component in the FTTH network architecture. It is the final - stage connection cable that directly links the optical distribution network (ODN) to the end - user's premises, such as homes or small businesses.

In the FTTH system, the overall network consists of a central office, feeder cables, distribution cables, and finally, the drop cables. The feeder cables carry high - capacity optical signals from the central office to distribution points, and the distribution cables further divide and route these signals to local areas. The FTTH Drop Cable then makes the last - mile connection, delivering high - speed optical signals right into the user's home or business. Its main function is to enable high - speed, reliable data transmission, including broadband internet, voice services, and high - definition video content, to meet the ever - growing demands of modern digital life. For example, when you stream 4K or 8K ultra - high - definition videos at home, download large files in a short time, or participate in real - time video conferences, the FTTH Drop Cable plays a vital role in ensuring smooth and fast data transfer.

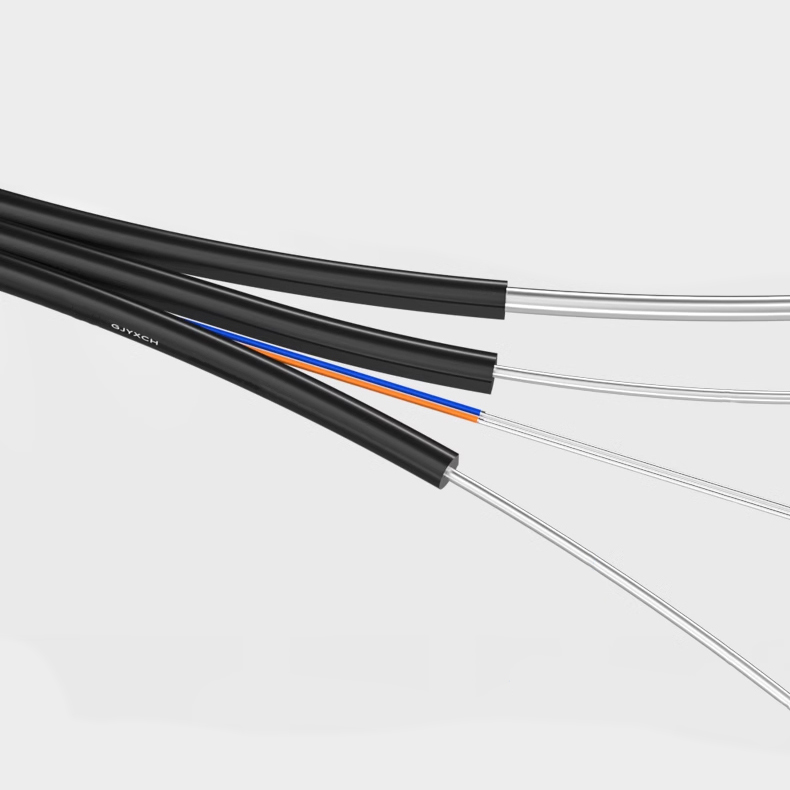

1.2 Structure Details

The structure of an FTTH Drop Cable is designed to protect the optical fibers and ensure optimal performance.

Fiber Core: At the heart of the FTTH Drop Cable are the optical fibers. These are typically made of high - purity silica glass. The most common types of optical fibers used in FTTH Drop Cables are single - mode fibers (SMF) and multi - mode fibers (MMF). Single - mode fibers have a very small core diameter, usually around 9 microns. They are mainly used for long - distance and high - speed data transmission because they can transmit light signals over long distances with minimal attenuation. This allows for the delivery of high - speed internet services from the service provider's central office to the end - user, even if the distance is several kilometers. Multi - mode fibers, on the other hand, have a larger core diameter, typically 50 or 62.5 microns. They are more suitable for shorter - distance applications within a building or a campus, as they can carry multiple light rays (modes) simultaneously, which is useful for local area network (LAN) connections in commercial buildings or multi - dwelling units.

Coating and Buffer Layer: Surrounding the fiber core is a coating and buffer layer. The coating is usually made of a soft material like acrylate, which provides initial protection to the fragile fiber core from mechanical stress and environmental factors such as moisture and dust. The buffer layer, often made of plastic, further cushions the fiber, absorbing any external forces that could potentially damage the fiber. It also helps to maintain the integrity of the fiber during installation and handling. For instance, when the cable is being pulled through conduits or bent around corners during installation, the buffer layer ensures that the fiber core is not strained or broken.

Strength Members: To enhance the tensile strength of the FTTH Drop Cable, strength members are incorporated. These are usually made of materials such as aramid fibers (e.g., Kevlar) or glass - fiber - reinforced plastic (GFRP). Aramid fibers are known for their high strength - to - weight ratio, which means they can withstand significant pulling forces without adding much weight to the cable. GFRP, on the other hand, provides good mechanical support and protection against bending and crushing. These strength members are placed around the fiber core and buffer layer, distributing the tension evenly when the cable is being installed or stretched, ensuring that the optical fibers inside remain intact.

Outer Sheath: The outermost part of the FTTH Drop Cable is the outer sheath. It is typically made of materials like polyethylene (PE), polyvinyl chloride (PVC), or low - smoke zero - halogen (LSZH) compounds. PE is a common choice for its good chemical resistance, water - proof properties, and relatively low cost. PVC is also widely used due to its flexibility and durability, but it may release harmful gases when burned. LSZH compounds are becoming increasingly popular, especially in applications where fire safety is a concern, such as in buildings. The outer sheath protects the internal components of the cable from various environmental factors, including sunlight, moisture, chemicals, and physical damage. It also provides electrical insulation, ensuring the safety of the cable during operation.

2. Characteristics of FTTH Drop Cable

2.1 Physical Properties

FTTH Drop cables have distinct physical properties that significantly influence their installation and application scenarios.

In terms of size, FTTH Drop cables are designed to be compact. For example, the popular butterfly - shaped (or "8 - shaped") FTTH Drop cables, also known as butterfly - style drop cables or ribbon drop cables, typically have a small cross - sectional area. The overall dimensions of a common two - fiber butterfly - shaped drop cable might be around 2.0mm x 3.0mm. This compact size makes it easy to install in tight spaces, such as within the narrow conduits or along the corners of walls in residential buildings. It can be conveniently routed through existing building infrastructure without the need for major renovations or large - scale cable management systems.

The weight of FTTH Drop cables is relatively light. This is mainly due to the use of lightweight materials in their construction, such as the use of aramid fibers as strength members instead of heavier metal wires in some cases. The lightweight nature of these cables reduces the load on the supporting structures during installation. For instance, when the cable is installed on poles or in overhead installations, the light weight minimizes the stress on the poles and the associated mounting hardware. It also makes the cable - handling process easier for installers, reducing fatigue during long - term installation work.

Flexibility is another key physical property of FTTH Drop cables. They are highly flexible, allowing them to be bent around corners and through complex routing paths. This is crucial for indoor installations where the cable may need to be routed around furniture, door frames, or other obstacles. The minimum bending radius of a typical FTTH Drop cable is often specified to ensure that the optical fibers inside are not damaged during bending. For example, a common single - mode FTTH Drop cable may have a minimum static bending radius of about 30mm and a minimum dynamic bending radius of around 15mm. This flexibility enables the cable to adapt to different installation environments, whether it's a newly constructed building with well - planned cable ducts or an older building with limited space for cable installation.

2.2 Optical Performance Features

The optical performance of FTTH Drop cables is of utmost importance for high - speed data transmission.

Low - loss characteristics are a fundamental aspect of FTTH Drop cables. In single - mode FTTH Drop cables, the attenuation of optical signals is kept to a minimum. For example, at a wavelength of 1310nm, the attenuation is typically less than 0.45dB/km, and at 1550nm, it is often less than 0.30dB/km. This low attenuation allows optical signals to travel long distances without significant degradation. In a FTTH network, this means that the service provider can deliver high - speed internet signals from the central office to the end - user's home over several kilometers of cable with minimal signal loss. As a result, users can enjoy high - quality services such as high - definition video streaming, online gaming, and large - file downloads without experiencing buffering or slow - down issues.

High - bandwidth capabilities are also a significant advantage of FTTH Drop cables. They are capable of supporting extremely high - speed data transmission. For instance, modern FTTH Drop cables can support bandwidths of up to 1Gbps or even 10Gbps in some advanced deployments. This high - bandwidth capacity is essential to meet the increasing demands of digital applications. With the growing popularity of 4K and 8K video content, virtual reality (VR), and cloud - based services, users require large amounts of data to be transferred quickly. The high - bandwidth of FTTH Drop cables enables multiple devices in a household to be connected to the internet simultaneously, each consuming significant amounts of data without affecting the performance of other devices. For example, a family can stream 4K movies on a smart TV, while a gamer is playing online in real - time and someone else is working from home using cloud - based software, all without any noticeable lag or slowdown in the network connection.

2.3 Durability and Environmental Adaptability

FTTH Drop cables are engineered to be durable and adaptable to various environmental conditions.

In terms of durability, they are constructed with materials that can withstand mechanical stress. The outer sheath, usually made of polyethylene (PE), polyvinyl chloride (PVC), or low - smoke zero - halogen (LSZH) materials, provides protection against abrasion, impact, and physical damage. For example, in outdoor installations where the cable may be exposed to wind, rain, and accidental contact, the robust outer sheath prevents the internal optical fibers from being damaged. The strength members within the cable, such as aramid fibers or glass - fiber - reinforced plastic (GFRP), enhance its tensile strength, ensuring that the cable can withstand pulling forces during installation and normal use without breaking.

These cables also exhibit excellent environmental adaptability. They can operate effectively in a wide range of temperatures. For instance, most FTTH Drop cables are designed to function properly in temperatures ranging from - 40°C to +60°C. This temperature tolerance allows them to be used in diverse climates, from extremely cold regions to hot and humid areas. In cold environments, the cable materials do not become brittle, and in hot conditions, they do not deform or lose their mechanical and optical properties. Additionally, FTTH Drop cables are resistant to moisture. The waterproof design of the cable, along with the moisture - resistant materials used in its construction, prevents water from infiltrating the cable and damaging the optical fibers. This is crucial for both outdoor and indoor installations, especially in areas prone to high humidity or water exposure, such as near water bodies or in basements.

3. Manufacturing Process

3.1 Raw Material Selection

The manufacturing of FTTH Drop cables begins with the careful selection of high - quality raw materials, as these materials directly impact the quality and performance of the final product.

Optical fibers are the most crucial raw material. High - purity silica glass is the primary choice for manufacturing optical fibers due to its excellent optical properties. For single - mode fibers, which are widely used in FTTH Drop cables for long - distance and high - speed data transmission, the silica glass needs to be extremely pure to minimize optical signal attenuation. The quality of the silica glass determines how effectively light signals can be transmitted over long distances. Impurities in the glass can scatter or absorb light, increasing attenuation and reducing the overall performance of the fiber.

Plastics play a significant role in the structure of FTTH Drop cables. Polyethylene (PE), polyvinyl chloride (PVC), and low - smoke zero - halogen (LSZH) compounds are commonly used for the outer sheath. PE is popular for its good chemical resistance, water - proof nature, and cost - effectiveness. PVC offers flexibility and durability, although it has some environmental drawbacks when burned. LSZH compounds are increasingly favored in applications where fire safety is a top priority, such as in buildings. These plastics protect the internal components of the cable from environmental factors like moisture, sunlight, and chemicals, and also provide electrical insulation.

Strength - enhancing materials are essential to ensure the cable can withstand mechanical stress. Aramid fibers, such as Kevlar, are widely used as strength members due to their high strength - to - weight ratio. They can endure significant pulling forces without adding excessive weight to the cable. Glass - fiber - reinforced plastic (GFRP) is another option, providing excellent mechanical support and protection against bending and crushing. These strength - enhancing materials are placed strategically around the fiber core and buffer layer to distribute tension evenly during installation and normal use, safeguarding the integrity of the optical fibers.

3.2 Key Manufacturing Steps

The manufacturing process of FTTH Drop cables involves several key steps, each with its own significance in ensuring the quality and performance of the final product.

Fiber Drawing: The first crucial step is fiber drawing. High - temperature heating is applied to the pre - form rod made of high - purity silica glass. As the rod is heated to a softened state, it is gradually pulled through a precision - designed die. This process is highly precise, with strict control over temperature, pulling speed, and tension. The temperature must be maintained within a specific range to ensure the glass has the right viscosity for smooth drawing. A too - high temperature can cause the glass to become too fluid, resulting in inconsistent fiber diameters, while a too - low temperature can lead to brittle fibers. The pulling speed and tension also need to be carefully adjusted to achieve the desired fiber diameter and mechanical properties. For example, in the production of single - mode fibers with a core diameter of about 9 microns, the drawing process requires extremely accurate control to meet the strict specifications. The drawn optical fibers are then coated with a protective layer, usually made of acrylate, to enhance their mechanical strength and protect them from initial mechanical stress and environmental factors.

Stranding: After the fiber drawing and coating process, multiple optical fibers are stranded together. This step is important for improving the cable's mechanical strength and flexibility. The stranding process involves twisting the optical fibers around a central core or among themselves in a specific pattern. The twist pitch, which is the distance over which the fiber makes one complete turn, is carefully controlled. A proper twist pitch ensures that the fibers are evenly distributed within the cable and can work together effectively. If the twist pitch is too large, the fibers may not be held firmly together, and if it is too small, the fibers may be over - stressed, leading to potential damage during installation or use. During stranding, strength - enhancing materials like aramid fibers or GFRP are also incorporated. These materials are placed around the optical fibers, providing additional support and protection. For instance, aramid fibers are often wound around the fiber bundle in a helical pattern, enhancing the cable's tensile strength and resistance to bending.

Sheath Extrusion: The final major step is sheath extrusion. In this process, a layer of plastic, such as PE, PVC, or LSZH, is extruded around the stranded optical fibers and strength - enhancing materials. The plastic is melted and forced through a die that shapes it into a protective outer sheath. The extrusion process requires careful control of parameters such as temperature, pressure, and extrusion speed. The temperature of the plastic must be high enough to ensure it flows smoothly through the die but not so high that it degrades the properties of the plastic. The pressure applied during extrusion determines the thickness and uniformity of the sheath. If the pressure is uneven, the sheath may have varying thicknesses, which can affect the cable's overall performance and durability. The extrusion speed needs to be coordinated with the production rate of the previous steps to ensure a continuous and efficient manufacturing process. Once the sheath is extruded, the FTTH Drop cable takes its final form, ready for further quality inspection and packaging.

3.3 Quality Control in Manufacturing

Quality control is an integral part of the FTTH Drop cable manufacturing process to ensure that the final products meet the required standards.

Optical Performance Testing: During the manufacturing process, optical performance testing is carried out at multiple stages. One of the key parameters tested is attenuation. Specialized optical instruments, such as optical time - domain reflectometers (OTDRs), are used to measure the attenuation of optical signals in the fibers. The OTDR sends a short pulse of light into the fiber and measures the back - scattered light. By analyzing the intensity of the back - scattered light at different points along the fiber, the attenuation can be accurately determined. This helps to identify any regions in the fiber where there may be excessive signal loss, which could be due to impurities, manufacturing defects, or improper handling. Another important optical performance parameter is bandwidth. The bandwidth of the optical fiber is tested to ensure that it can support the high - speed data transmission required for modern applications. This is usually done using equipment that can generate and measure high - frequency optical signals. The fiber's ability to transmit signals at different frequencies is evaluated to ensure it meets the specified bandwidth requirements.

Physical Performance Testing: Physical performance testing is equally important. Tensile strength testing is conducted to ensure that the cable can withstand the pulling forces it may encounter during installation and normal use. Specialized tensile testing machines are used to gradually apply a pulling force to the cable until it reaches its breaking point. The maximum force the cable can withstand is measured, and this value must meet the minimum requirements specified in the relevant standards. Bending radius testing is also carried out. The cable is bent around a mandrel of a specified radius, and the optical performance of the fiber inside is monitored during and after bending. This helps to determine the minimum bending radius that the cable can tolerate without causing significant signal degradation or fiber damage. Additionally, environmental testing is performed to assess the cable's performance in different environmental conditions. For example, the cable may be subjected to high - and low - temperature cycling to simulate extreme weather conditions. It may also be tested for its resistance to moisture, chemicals, and UV radiation. These environmental tests help to ensure that the cable can function reliably in various real - world applications.

4. Applications in Modern Communication

4.1 Residential Broadband Connectivity

FTTH Drop cables have become the cornerstone of high - speed residential broadband connectivity. In today's digital - first households, the demand for fast and reliable internet access is insatiable. FTTH Drop cables meet this demand by providing gigabit - speed internet directly to homes.

For example, in a typical suburban home, an FTTH Drop cable enables seamless 4K and even 8K video streaming on multiple smart TVs simultaneously. Family members can enjoy their favorite high - definition movies, TV shows, or live sports events without any buffering issues. This is because the high - bandwidth capabilities of FTTH Drop cables can handle the large amounts of data required for ultra - high - definition video content.

Online gaming has also been revolutionized by FTTH Drop cables. Gamers can participate in real - time multiplayer online games, such as Fortnite or Call of Duty, with extremely low latency. The low - loss characteristics of the cables ensure that the data packets sent between the gamer's console or PC and the game server are transmitted quickly and accurately. This allows for a smooth and responsive gaming experience, where every move and action is reflected instantaneously in the game, giving players a competitive edge.

Moreover, with the increasing popularity of remote work and online learning, FTTH Drop cables play a crucial role. Remote workers can connect to their company's virtual private networks (VPNs) securely and access work - related files, databases, and applications in real - time. They can participate in high - definition video conferences with colleagues around the world without any disruptions, ensuring effective communication and collaboration. Similarly, students can access online educational resources, attend virtual classrooms, and submit assignments seamlessly, enhancing their learning experience.

4.2 Business and Office Use

In the business and office environment, FTTH Drop cables are essential for maintaining high - productivity and efficient operations.

For small and medium - sized enterprises (SMEs), FTTH Drop cables provide the high - speed data transfer necessary for cloud - based services. Many SMEs rely on cloud - based accounting software, customer relationship management (CRM) systems, and project management tools. With FTTH Drop cables, employees can access these cloud - based applications in real - time, enabling quick data retrieval and updates. For instance, a sales team can instantly access customer information stored in a cloud - based CRM system, allowing them to provide better customer service and close deals faster.

Large corporations also benefit significantly from FTTH Drop cables. In data - intensive industries such as finance, media, and technology, the need for high - speed and reliable data transmission is critical. Financial institutions, for example, rely on FTTH Drop cables to execute high - frequency trading. These cables enable the rapid transfer of market data, trade orders, and transaction confirmations. The low - latency and high - bandwidth features of FTTH Drop cables ensure that traders can respond to market changes in real - time, maximizing their trading opportunities and minimizing risks.

In office buildings, FTTH Drop cables support the integration of multiple communication systems. Voice over Internet Protocol (VoIP) phone systems, which are becoming increasingly popular in offices, require a stable and high - speed internet connection. FTTH Drop cables provide the necessary bandwidth to ensure clear voice communication, with minimal dropped calls or audio glitches. Additionally, they support video surveillance systems, allowing businesses to monitor their premises remotely in high - definition, enhancing security and safety.

4.3 Integration with Smart Home Systems

The integration of FTTH Drop cables with smart home systems has opened up a world of possibilities for homeowners. Smart home devices are becoming more prevalent, and FTTH Drop cables act as the backbone for their seamless operation.

Smart lighting systems, such as Philips Hue, can be controlled remotely through a smartphone or a voice - controlled assistant like Amazon Alexa or Google Assistant. With FTTH Drop cables, the communication between the smart bulbs, the hub, and the user's device is fast and reliable. For example, a homeowner can turn on or off the lights, adjust the brightness, or change the color of the lights while away from home, simply by using their mobile app.

Smart thermostats, like the Nest Thermostat, also rely on FTTH Drop cables to function optimally. These thermostats can learn the homeowner's temperature preferences over time and adjust the heating or cooling system accordingly. They can be controlled remotely, allowing users to pre - heat or pre - cool their homes before they arrive. The high - speed and stable connection provided by FTTH Drop cables ensure that the thermostat receives real - time temperature data from sensors placed throughout the home and can make accurate adjustments.

Security systems are another area where FTTH Drop cables play a crucial role. Smart security cameras, door locks, and motion sensors can be integrated into a comprehensive security system. With FTTH Drop cables, homeowners can receive real - time alerts on their smartphones when there is any suspicious activity detected. They can also view live video feeds from their security cameras, both locally and remotely, to monitor the security of their homes. For example, if a motion sensor is triggered, the homeowner can immediately access the live video feed from the nearby security camera to see what caused the alert, providing them with peace of mind.

5. Installation and Maintenance

5.1 Installation Guidelines

Installing FTTH Drop cables requires careful planning and the use of proper techniques to ensure optimal performance.

Installation Tools:

- Fiber Optic Cable Strippers: These are essential for removing the outer sheath, buffer layer, and coating of the FTTH Drop cable to expose the optical fibers. There are different types available, such as mechanical strippers and chemical strippers. Mechanical strippers are more commonly used due to their precision and ease of use. For example, a good - quality mechanical fiber optic cable stripper can accurately remove the outer layers without damaging the delicate optical fibers inside.

- Fiber Optic Cutters: High - precision fiber optic cutters are used to make clean and precise cuts on the optical fibers. The cut end of the fiber must be extremely smooth to ensure efficient light transmission. A well - calibrated fiber optic cutter can achieve a cutting angle deviation of less than 0.5 degrees, which is crucial for minimizing signal loss during connection.

- Fiber Optic Splicers: Fusion splicers are widely used for permanently joining two optical fibers. They use an electric arc to melt the ends of the fibers and fuse them together. The splicing process requires strict control of parameters such as arc current, arc time, and fiber alignment. For instance, a modern fusion splicer can achieve a splice loss of less than 0.05dB, ensuring high - quality optical signal transmission. In some cases, mechanical splicers may also be used, which use a mechanical connection method to join the fibers.

- Testing Equipment: Tools like optical time - domain reflectometers (OTDRs) and optical power meters are necessary for testing the integrity and performance of the installed FTTH Drop cable. An OTDR can detect fiber breaks, splice losses, and other defects along the length of the cable. It works by sending a short pulse of light into the fiber and measuring the back - scattered light. An optical power meter, on the other hand, measures the power of the optical signal at different points, helping to ensure that the signal strength meets the required standards.

Installation Steps:

- Route Planning: Before installation, carefully plan the route of the FTTH Drop cable. Consider factors such as the location of the optical distribution network (ODN) termination point, the entry point into the building, and the desired location of the optical network terminal (ONT) inside the premises. The route should be as straight as possible to minimize cable bending and signal loss. For example, in a residential building, the cable may be routed along the exterior wall, through a conduit, and then into the home through a pre - drilled hole near the utility entrance.

- Cable Installation: When installing the cable, ensure that it is properly supported and protected. For outdoor installations, if the cable is run along poles, use cable hangers or messenger wires to support it. In conduit installations, make sure the conduit is large enough to accommodate the cable without squeezing or bending it excessively. The minimum bending radius of the FTTH Drop cable should be strictly adhered to during installation. For a typical single - mode FTTH Drop cable, the minimum static bending radius is often around 30mm, and the minimum dynamic bending radius (when the cable is being installed or moved) is about 15mm. Bending the cable beyond these limits can cause signal attenuation or even fiber breakage.

- Connection and Termination: Once the cable is in place, connect it to the ODN and terminate it at the ONT. This involves stripping the cable ends, splicing or connecting the optical fibers, and protecting the connections with appropriate connectors and splice enclosures. For splicing, follow the manufacturer's instructions for the fusion splicer or mechanical splicer. When using connectors, ensure that they are properly inserted and tightened to achieve a secure and low - loss connection. For example, SC (Subscriber Connector) or LC (Lucent Connector) connectors are commonly used in FTTH installations, and they should be inserted into the corresponding ports on the ODN and ONT with care to avoid misalignment.

Installation Precautions:

- Environmental Considerations: Avoid installing the FTTH Drop cable in areas with high humidity, extreme temperatures, or strong electromagnetic interference. If the cable must be installed in such an environment, take appropriate protective measures. For example, in a high - humidity area, use a cable with a moisture - resistant outer sheath and ensure that all connections are properly sealed. In an area with strong electromagnetic fields, such as near power lines or radio transmitters, use a cable with good shielding properties or route the cable at a safe distance from the sources of interference.

- Avoiding Physical Damage: During installation, be careful not to damage the cable. Do not pull the cable too hard, as this can stretch or break the optical fibers inside. Also, avoid sharp objects coming into contact with the cable, as they can puncture the outer sheath and damage the fibers. When passing the cable through tight spaces or around corners, use cable guides or bend - limiting devices to prevent excessive bending. For instance, when the cable is being routed through a wall with a narrow hole, use a rubber grommet to protect the cable from abrasion.

- Testing During Installation: Continuously test the cable during the installation process. Use an OTDR to check for any fiber breaks, splice losses, or other issues as each section of the cable is installed and connected. This allows for early detection and correction of problems, saving time and effort in the long run. If a problem is detected, carefully check the installation steps, the connections, and the cable itself to identify and resolve the issue.

5.2 Maintenance Requirements

Regular maintenance of FTTH Drop cables is crucial to ensure their long - term stable operation and reliable performance.

Regular Inspection:

- Visual Inspection: Conduct regular visual inspections of the FTTH Drop cable. Check the outer sheath for any signs of damage, such as cuts, abrasions, or cracks. Look for signs of rodent damage, especially in areas where rodents are present. Inspect the cable supports, such as hangers and brackets, to ensure they are still in place and in good condition. For example, if the outer sheath of the cable shows signs of fraying, it may be a sign of physical stress or damage, and further investigation is needed.

- Connection Inspection: Examine all the connections, including splices and connectors. Check for loose connections, which can cause signal loss or intermittent service. Inspect the splice enclosures and connector housings to ensure they are properly sealed and protecting the connections. A loose SC connector, for instance, can result in a significant increase in signal attenuation, so it's important to ensure that all connectors are firmly seated.

- Environmental Monitoring: Monitor the environment around the FTTH Drop cable. Check for any changes in the environment that could potentially affect the cable, such as construction activities nearby, changes in temperature or humidity levels, or the growth of vegetation that could come into contact with the cable. If construction is taking place near the cable route, take precautions to protect the cable from accidental damage.

Cleaning:

- Fiber End Cleaning: The ends of the optical fibers and the connectors should be cleaned regularly. Use lint - free wipes or swabs soaked in isopropyl alcohol to clean the fiber ends and connector surfaces. This helps to remove dust, dirt, and other contaminants that can cause signal attenuation. For example, a dirty fiber end can scatter light, increasing the signal loss. Cleaning the fiber ends and connectors at least once every few months can significantly improve the optical performance of the cable.

- Cable Surface Cleaning: Clean the outer surface of the FTTH Drop cable, especially in areas where it may accumulate dirt, dust, or other debris. A clean cable surface not only looks better but also helps to prevent the build - up of substances that could potentially damage the outer sheath over time. Use a soft, damp cloth to gently wipe the cable surface, being careful not to apply too much pressure that could damage the cable.

Fault Detection and Troubleshooting:

- Using Testing Equipment: Regularly use testing equipment such as OTDRs and optical power meters to detect any faults or performance degradation in the FTTH Drop cable. An OTDR can quickly identify the location of fiber breaks, excessive splice losses, or other defects in the cable. If the optical power measured by an optical power meter is lower than the expected value, it may indicate a problem with the cable, such as a damaged fiber or a poor connection.

- Fault Isolation: When a fault is detected, isolate the problem area. First, determine whether the problem is in the cable itself, the connections, or the associated equipment. For example, if the OTDR shows a high - loss point, check the splice or connection at that location. If the problem persists after checking the connections, the cable may be damaged, and further inspection or repair may be required.

- Repair and Replacement: Once the fault is identified, take appropriate action to repair or replace the damaged components. If it's a loose connection, tighten it. If a fiber is broken, splice it or replace the damaged section of the cable. In some cases, if the damage is extensive, the entire cable may need to be replaced. When replacing components, use high - quality parts that are compatible with the existing system to ensure reliable operation.

6. Future Developments and Trends

6.1 Technological Advancements on the Horizon

The future of FTTH Drop cable technology holds several exciting prospects. One of the significant areas of development is in the use of higher - performance materials. Researchers are exploring new types of optical fibers with even lower attenuation and improved bending resistance. For example, some new - generation optical fibers are being designed to have an attenuation of less than 0.2dB/km at 1550nm, which would significantly extend the reach of fiber - optic networks without the need for additional signal boosters. These advanced fibers may also have enhanced resistance to environmental factors, such as better resistance to humidity - induced degradation, ensuring more reliable long - term performance.

In terms of manufacturing processes, the trend is towards more advanced and automated techniques. Advanced manufacturing technologies, such as 3D printing, are being investigated for the production of FTTH Drop cables. 3D printing could potentially enable the creation of customized cable structures with precise internal geometries. This could lead to improved fiber protection, reduced signal loss, and enhanced overall cable performance. Additionally, the use of artificial intelligence (AI) and machine learning in the manufacturing process is expected to increase. AI can be used to monitor and optimize the manufacturing process in real - time, ensuring consistent quality, reducing waste, and improving production efficiency. For instance, AI - powered sensors can detect even the slightest variations in the raw materials or manufacturing parameters and make instant adjustments to maintain the quality of the cables.

6.2 Market Outlook and Expansion Potential

The market outlook for FTTH Drop cables is highly promising. With the continuous growth in the demand for high - speed internet globally, the market for FTTH Drop cables is expected to expand significantly in the coming years. The increasing popularity of 4K and 8K video streaming, virtual reality (VR), and augmented reality (AR) applications is driving the need for ultra - high - speed broadband connections. As more households and businesses upgrade to these high - bandwidth services, the demand for FTTH Drop cables, which are essential for delivering such services, will also rise.

Moreover, the expansion of smart cities initiatives around the world will further fuel the demand for FTTH Drop cables. Smart cities rely on a vast network of interconnected devices and sensors, all of which require high - speed and reliable data communication. FTTH Drop cables will play a crucial role in enabling the seamless operation of smart city infrastructure, including smart transportation systems, intelligent energy management, and advanced environmental monitoring. For example, in a smart city, traffic lights can be connected to a central control system via FTTH Drop cables, allowing for real - time traffic monitoring and dynamic traffic signal adjustments.

In addition, the development of 5G networks will have a positive impact on the FTTH Drop cable market. Although 5G is a wireless technology, it still requires a robust fiber - optic backbone for backhaul connections. FTTH Drop cables will be an integral part of this fiber - optic infrastructure, providing the high - speed connections needed to support the massive data traffic generated by 5G networks. As 5G coverage expands, the demand for FTTH Drop cables in both urban and rural areas will increase.

Geographically, emerging economies in Asia - Pacific, Latin America, and Africa are expected to be significant growth markets for FTTH Drop cables. These regions are currently in the process of rapidly developing their telecommunications infrastructure to meet the growing digital demands of their populations. Governments in these areas are investing heavily in broadband expansion projects, creating substantial opportunities for the deployment of FTTH Drop cables. For example, many countries in Southeast Asia are implementing national broadband plans to improve internet access in rural and underserved areas, which will drive the demand for FTTH Drop cables in the coming years.

Conclusion

In conclusion, FTTH Drop cables are of utmost importance in modern communication networks. Their ability to provide high - speed, reliable, and stable data transmission has transformed the way we access information, communicate, and conduct business. With their low - loss characteristics, high - bandwidth capabilities, and excellent durability, they have become the preferred choice for delivering broadband services to residential and commercial users alike.

The applications of FTTH Drop cables are diverse and far - reaching, from enabling high - definition video streaming and seamless online gaming at home to supporting critical business operations and powering the integration of smart home systems. As technology continues to evolve, the future of FTTH Drop cables looks even more promising. Technological advancements in materials and manufacturing processes are set to further enhance their performance, while the growing market demand, especially driven by the expansion of high - bandwidth applications and smart city initiatives, ensures their continued growth and widespread deployment.

In the coming years, we can expect FTTH Drop cables to play an even more significant role in bridging the digital divide, bringing high - speed internet access to more remote and underserved areas. They will be at the forefront of the development of next - generation communication networks, supporting emerging technologies such as 5G backhaul, augmented reality, and the Internet of Things. Overall, FTTH Drop cables are not just a crucial component of today's communication infrastructure but also a key enabler of the digital future.

- Learn about FTTH Drop Cable: the key to high-speed home broadband. Discover its structure, low-loss performance, easy installation & use in smart homes. Boost stable connectivity for residences/businesses.

- FTTH Drop Cable: essential for fast home internet. Explore its durability, environmental adaptability, and integration with smart systems. Get tips for installation & maintenance.

- Find out why FTTH Drop Cable matters for home connectivity. It offers high bandwidth, reliability, and works for residences/ offices. Learn about its manufacturing & future trends.